For a CO2-neutral future

Fuels of the Future

DEUTZ engines are used in many different applications worldwide. The quality of the fuel is decisive for the service life of DEUTZ engines and for the minimisation of service costs. The fuel also plays a key role in determining the emissions produced by modern combustion engines.

Fuels of the Future

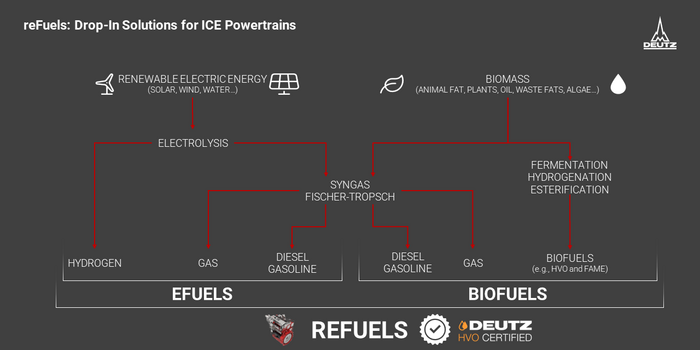

Because of their high payloads and long operating times, large tractors and construction machinery require energy sources with high energy density and short refuelling times. Furthermore, CO2-neutral operation of combustion engines will be crucial in the future due to stricter climate protection targets, which can be achieved by using alternative fuels, so-called re-fuels.

ReFuels are produced on the basis of renewable energies. These include hydrogen, synthetically produced hydrocarbons and advanced biofuels as defined by RED II (Renewable Energy Directive). Advanced biofuels use raw materials that do not compete with food crops.

For example, diesel engines can use HVO (Hydrotreated Vegetable Oil), which is produced without fossil resources by hydrogenating sustainable biogenic residues. This can significantly reduce pollutant and CO2 emissions by up to 95%.

On the other hand, CO2-neutral engine operation is even possible in the future with so-called e-fuels. E-fuels are synthetic fuels produced from hydrogen and carbon dioxide using electricity. Synthetic fuels differ from conventional fuels in the production process and the resulting change in chemical structure. They can be derived from renewable sources and are known as RFNBO (Renewable Fuels of Non-Biological Origin).

Overview of different kind of fuels

Conventional Fuels

Paraffinic diesel fuels are produced on an industrial scale using the Fischer-Tropsch process based on synthesis gas. Basically, this process can use fossil raw materials such as natural gas (GtL - gas-to-liquid) or biomass (BtL - biomass-to-liquid).

In the future, the same process will be used to produce eDiesel using regeneratively produced hydrogen and CO2 from combustion processes or the air, enabling CO2-neutral operation of combustion engines. Currently, by hydrogenating sustainable biogenic oil-containing residual waste, a large part of the paraffinic fuel is produced as HVO. These so-called XtL fuels are characterised not only by reduced CO2 emissions, but also by lower emissions (NOx, particulates) and better fuel quality regarding cold behaviour and oxidation stability compared to conventional diesel fuel.

The fuel / HVO produced in this way meets the specifications of EN 15940 or ASTM D975. DEUTZ has almost all series up to EU V and US Tier 4 emission standards. Due to their composition, these fuels can also be blended with fossil diesel in any ratio. The use of HVO in all existing engines is practically a matter of course and can - in future supplemented by eDiesel - make a decisive contribution to the defossilisation of diesel engines.

Diesel fuel is a mixture of hydrocarbons. The quality of the fuel varies greatly from country to country. In countries such as the USA, Japan or the European Union, diesel fuels are optimised to meet the particular challenges of low emissions and the use of exhaust aftertreatment systems. In other countries, however, there are still fuels of lower quality (sulphur content, lubricity, contamination and cetane number as a measure of combustion behaviour).

Alternative Fuels

Biodiesel or FAME (Fatty Acid Methyl Ester) is a so-called transesterified vegetable oil that has been adapted to the properties of diesel fuel. In Europe, rapeseed oil is often the raw material base, so the term rapeseed methyl ester (RME) is often used. In addition to this, recycled waste oils are also used as a raw material on a large scale.

In Europe, but also in many non-European countries such as the USA, Mexico, Brazil, Argentina, Malaysia and Indonesia, biodiesel is mainly used as a diesel/biodiesel blend of up to 40%, but in some cases also as a pure fuel.

All DEUTZ engines in Europe and the USA are approved to run on the following standard fuels according to EN 590 and ASTM D975, which allow blends of up to 7% and 5% respectively. In addition, there are many approvals for Tier 4, EU IV and V engines for higher biodiesel blends (e.g. EN 16734 / EN 16709 / ASTM D7467) and for pure fuels to EN 14214.

Liquefied petroleum gas (LPG) is a mixture of propane and butane that is liquid at room temperature and low compression (< 10 bar). The main advantages of LPG are the high energy density in the gas tank and the reduced CO2 emissions during combustion in the engine compared to diesel engines of similar size. LPG is usually produced during the refining of crude oil. It is also produced during the production of HVO (Hydrotreated Vegetable Oils) as Bio-LPG or, in the future, as ePropane with a very low greenhouse gas emission potential.

The main constituent of natural gas is methane. Depending on how the natural gas is stored, transported and refueled, the term CNG (compressed natural gas) or LNG (liquefied natural gas) is used when the natural gas is liquefied by severe cooling and can then remain liquid in a storage container. Due to its clean combustion and lower CO2 emissions compared to diesel engines of comparable power, natural gas has become an increasingly popular fuel for internal combustion engines in recent years. In addition to fossil gas sources, methane can also be produced by fermenting biomass or by methanising renewable hydrogen with CO2. This is known as biomethane or e-methane.

Hydrogen is produced by electrolysis using renewable electricity. One way of using hydrogen for transport is to produce synthetic gaseous and liquid fuels. Hydrogen is then used as an intermediate product in the production of synthetic methane (power-to-gas methane/PtG methane) or eFuels (also power-to-liquids/PtL).

HVO (hydrotreated vegetable oil) is a renewable fuel that contributes to the reduction of dependence on fossil fuels as well as the reduction of CO2 emissions in the transport sector. It can be used in almost all modern DEUTZ engines without modification and offers a sustainable alternative to fossil fuel. It can be used in blends without restriction. Typically, public petrol stations use blends with of up to 26% HVO in diesel that fall under the current EN 590 diesel standard.

Renewable propane’s carbon intensity — or the carbon emitted for every unit of energy it produces — is lower than conventional propane because it’s produced from bio-based or renewable sources. It can be made from a variety of renewable feedstocks. The most common form of renewable propane today is a byproduct of renewable diesel (HVO) and sustainable aviation fuel made primarily from plant and vegetable oils, animal fats, or used cooking oil. As it is molecularly identical to conventional propane, it can be used in existing propane capable engines without any modification at all.