Fuels of the Future

HVO - Compatible with modern diesel engines

HVO (Hydrotreated Vegetable Oil) is a renewable fuel that helps to reduce dependence on fossil fuels and cut CO2 emissions. It can be used in all modern DEUTZ engines without modification and offers a sustainable alternative to fossil fuels.

Benefits of Hydrotreated Vegetable Oil

Climate friendly

Reduces CO2 up to 90% and reduces NOx and particulates.

No Food vs. Fuel Debate

Made from raw feedstock such as wastes, residues and fats.

Drop-In Solution

Available and ready to run, compatible with modern diesel engines.

FAQ

Hydrotreated vegetable oil (HVO) is a paraffinic diesel fuel produced from renewable resources such as vegetable oils or animal fats. It is a cleaner fuel, reducing dependence on fossil fuels and cutting CO2 emissions. It is a sustainable alternative to fossil diesel fuel and can be used in all modern DEUTZ engines without modification. There are no restrictions on the use in blends. Typically, a diesel blend with up to 26% HVO together with 7% biodiesel is available at public filling stations, which then falls under the current EN 590 diesel standard.

Essentially, many raw materials can be used as feedstock for HVO. While diesel fuel is a mixture of different petroleum-based hydrocarbons, HVO is a renewable fuel. Its chemical composition is similar to that of fossil diesel. In addition to vegetable oils, residual oils and fats are also used to produce this type of fuel.

HVO is produced industrially by hydrogenating vegetable and animal oils and fats (called triglycerides or fatty acids) in a refinery. The process is similar to the conventional refining of crude oil, but there are a number of steps required in production that may differ. It is different from FAME, which is made from oil-rich food and feed, including rapeseed, sunflower and soybean oil. So, this is not a debate about food versus fuel, but about advanced biofuels.

HVO is a pure diesel fuel with a similar chemical composition to fossil diesel. It can be used by all diesel vehicles and engines. With up to 90% less greenhouse gas emissions it offers the same high performance as fossil diesel while also reducing emissions of harmful substances such as hydrocarbons and other substances. In addition, its high cetane number ensures efficient and clean combustion at low temperatures. With a CFPP (Cold Filter Plugging Point) of max. - 22°C, HVO meets the criteria for winter diesel.

HVO fuel offers a number of benefits. These include

- High oxidation and storage stability, which is particularly important for standby generators with long downtimes.

- The year-round cold property of - 22°C, which eliminates the need for separate winter fuel.

- The high cetane number and chemical structure, which significantly reduce nitrogen oxide and particulate levels when used in engines without exhaust gas treatment (emergency power generators).

- The greenhouse gas reduction potential of up to 90%, enabling near CO2-neutral operation.

- Compatible with all modern diesel engines - immediately available and ready to run!

- Cleaner and more efficient than conventional diesel, with up to 50% fewer pollutants and particulates

- Made from a variety of renewable feedstocks including waste, residues and grease

- 100% renewable and sustainable resources

HVO is produced from used cooking oils and residual and waste materials. FAME is produced from oil-rich food and animal feed, including rapeseed, sunflower and soybean oil.

Basically, biodiesel (FAME) and HVO can be produced from the same raw materials. Biodiesel is produced by a process called transesterification. In this process, the triglyceride - i.e. the oil - is converted into biodiesel and glycerine using methanol. In the production of HVO, on the other hand, hydrogenation with H2 is used to obtain HVO. Triglyceride is converted with H2 into paraffinic diesel (HVO) and biopropane. Domestic products and cultivated biomass are mainly used for biodiesel, while residues are more commonly used for HVO.

In contrast to biodiesel, the paraffinic structure of HVO differs only slightly from fossil diesel. With a cetane rating of over 70, HVO burns more cleanly than biodiesel or conventional diesel (cetane rating of 51), generates significantly fewer emissions, and leaves much less residue in the engine. HVO is also easier to store and works better in cold weather than biodiesel.

Almost all modern DEUTZ engines are already approved for HVO under the current EU V emissions standard. CO2-neutral operation is therefore already possible. HVO meets the standards set in DIN EN 15940, and all modern DEUTZ diesel engines that meet the EU IV and V emissions standards are approved to run on HVO. In Germany, HVO is currently only approved for use in commercial vehicle fleets. Following a decision by the Bundestag on November 22, 2023, and subject to approval by the Bundesrat (second chamber of the German parliament), paraffinic diesel fuels such as HVO are expected to go on sale at public filling stations in May 2024 as pure fuels for all vehicles. This is already common practice in most EU member states. The use of HVO and the addition of so-called eFuels in the medium term are one of the main pillars of sustainable climate protection in off-road applications.

You can find a list of all suitable engines here.

Europe already has around 10 million tonnes of HVO fuel production capacity. At the moment, HVO is only available to commercial customers in Germany. However, with the new version of the 10th BImSchV, it will also be available at public filling stations in a relatively short time, following the decision of the Bundestag.

In recent years, the amount of HVO produced in the European Union has increased significantly. From 0.5 billion litres in 2011 to 4 billion litres in 2021, with an upward trend. By 2025, production is expected to reach 30 billion litres. As demand continues to grow, the refuelling infrastructure in Germany is being expanded accordingly.

Although 100% HVO fuel is not yet available at public filling stations in Germany, a blend of 26% HVO with fossil diesel is currently permitted. Engines must have manufacturer approval for HVO use.

HVO is made from 100 percent renewable resources, ensuring that carbon emitted during combustion is offset as part of a cycle. Due to the use of some fossil hydrogen and the carbon emissions in the logistics chain, not all CO2 can be avoided, with the reduction reaching up to 90 percent1.

1Based on the EU’s Renewable Energy Directive (RED II – 2018/2001/EU)

Using HVO instead of fossil diesel significantly reduces CO2 emissions over the entire life cycle of the fuel. Neste My Renewable Diesel offers a CO2 reduction of up to 90% compared to fossil diesel. The remaining 10% of HVO's emissions come mainly from transport and the production process, which currently involves the addition of grey hydrogen. If green hydrogen and sustainable fuels were used in transport, this could be 100% in the future. The fuel itself "fuel use" is 100% CO2-neutral.

HVO is the quickest way to protect the climate that we can implement right now.

No engine modification is required to use HVO. This means that switching to HVO fuel requires no additional investment. In addition, the fuel can be blended with fossil diesel in any ratio. Pure HVO operation is also possible. Unlike fossil diesel, hydrotreated vegetable oil is less sensitive to cold. This avoids flocculation and the need to switch between summer and winter diesel. There is also less corrosion of key engine components because the fuel contains no aromatics. HVO fuel therefore has a longer service life. Furthermore, the fuel does not tend to develop bio-cultures, the so-called "diesel pest". Compared to conventional diesel, there is also no difference in performance.

HVO operation is possible without any technical modifications. Only the engine must have the manufacturer's approval for HVO operation. This means that no expensive and resource-intensive new vehicles are required for the use of hydrotreated vegetable oil. Around 2 million modern DEUTZ engines are currently in use that can contribute to climate protection with HVO.

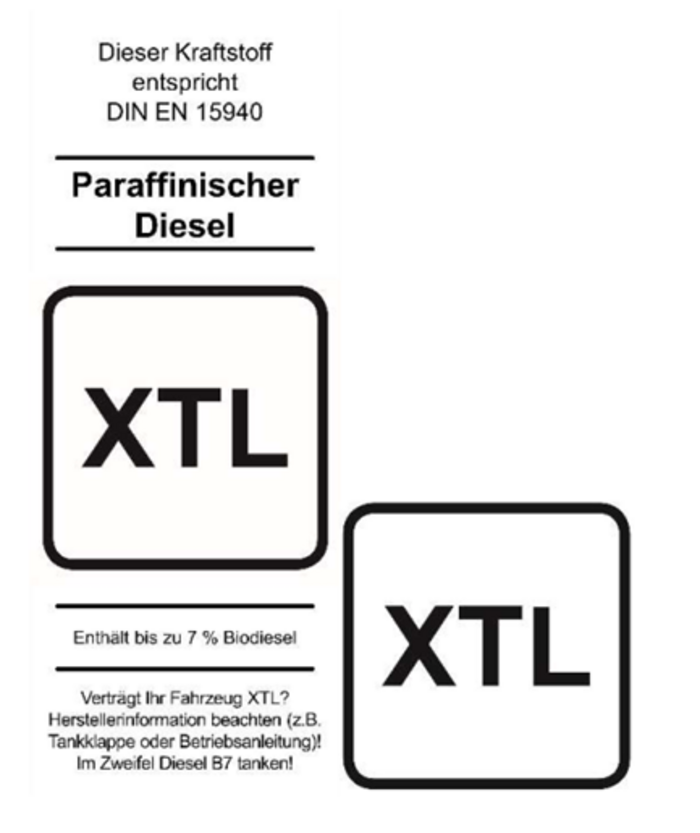

The user manual and fuel filler cap of modern cars and lorries approved for HVO are marked with the XTL symbol. Mandatory labeling does not apply to older vehicles and mobile machinery. If in doubt, the manufacturer can be contacted for clarification, and lists of approved vehicles are available online from HVO distributors.

HVO can be mixed and used with fossil-based diesel in any ratio. As HVO basically fulfils all the parameters of conventional diesel fuel standard EN 590 (B7) apart from density, fuels containing up to 26 percent HVO are already available at public filling stations (add 7 percent biodiesel and that amounts to 33 percent renewable content in diesel). These fuels can be used in all diesel engines without restriction.

HVO is an advanced biofuel. The Renewable Energy Directive RED II (EU 2018/2001) of December 11, 2018 defines in Annex IX, parts A and B, which raw materials are permitted in order to avoid any debate around food vs. fuel. In addition, the use of palm oil in biofuels is prohibited in Germany and the EU.

HVO is made from 100 percent renewable resources, ensuring that carbon emitted during combustion is offset as part of a cycle. Due to the use of some fossil hydrogen and the carbon emissions in the logistics chain, not all CO2 can be avoided, with the reduction reaching up to 90 percent1.

1Based on the EU’s Renewable Energy Directive (RED II – 2018/2001/EU)

The switch to HVO allows DEUTZ to improve its environmental footprint immediately. Converting our entire fleet to electric drives would take longer and be much more expensive, and it is not always possible, or sensible, to convert every vehicle and every engine, for example field test vehicles and gensets. Furthermore, the actual reduction in carbon emissions is around 50 percent1 for an electric vehicle, but up to 90 percent for a diesel engine run on HVO.

1Based on the current electricity mix in Germany (434g/kWh in 2022)

Global HVO production capacity is currently 10 million tonnes and rising, enough to cover current demand in Germany’s agricultural more than sector six times over1.

1Use of renewables in agricultural machinery. KTBL (2023)

HVO complies with the DIN EN 15940 standard for paraffinic diesel fuels.

The high cetane number ensures efficient and clean combustion. HVO has good low-temperature stability, meeting the criteria for winter diesel with a CFPP of max. -22°C. In addition, it is free of aromatics and can be stored for long periods of time without any loss of quality or increase in water content.

HVO is a renewable fuel produced by hydrotreating oils and fats from biomass, mainly waste and residues. In contrast, eFuels are based on the extraction and conversion of CO2 using hydrogen from water electrolysis. This enables the production of hydrocarbon chains that can be used as fuel. When this eFuel process is used to produce synthetic diesel fuel, the chemical composition is very similar to HVO. It must therefore also comply with DIN EN 15940 (paraffinic diesel fuels). In addition to HVO, eFuels also have a significant impact on the reduction of greenhouse gases. In this case, no additional CO2 greenhouse gas is released into the atmosphere during combustion. Both solutions are needed to support the energy transition and replace fossil fuels.

This is not a problem. In general, all modern engine families, as well as most older engine series, are approved for paraffinic fuel to EN 15940. This includes HVO.

In fact, there are advantages to its use:

- Due to its chemical structure, HVO has excellent oxidation behaviour in contrast to biodiesel and therefore long storage stability.

- Cold weather performance equivalent to winter diesel

- The use of HVO reduces CO2 emissions by up to 90%.

- For engines without EAT, exhaust emissions are reduced, especially particulates.

Although the EN 15940 specification for paraffinic diesel/HVO would allow up to 7% biodiesel content, pure HVO is generally sold.

This should be guaranteed by the supplier as the storage stability of HVO/biodiesel blends tends to deteriorate.

DEUTZ opens first HVO filling station at its factory site in Cologne

All diesel-powered vehicles of DEUTZ AG can now be refueled at the site with HVO.

Learn More